Here you can find useful information about blocks

Ratings in this catalogue are applicable only to new products.

The safe working load (S.W.L.) or working load limit (W.L.L.) of each Blue Line-block may be affected by wear, misuse, overloading, corrosion, deformation, intentional alteration and other use conditions.

Working loads shown are the maximum load the block is authorized to support under normal environmental conditions, chock loading and abnormal conditions must be taken into account when selecting the blocks. Regular inspection must be conducted to ensure the equipment continues to meet the required standard.

Blue Line blocks generally are intended for tension or pull. Side-loading must be avoided,as it excerts additional force or loading for which the product is not designed to accommodate.

Welding of or to load supporting parts or products can be hazardous. Knowledge of materials, heat-treatment and welding procedures is necessary for proper welding. The Blue Line should be consulted for information.

All blocks must be regularly inspected to monitor its condition. The frequency of inspection depends upon frequency and period of block use as well as environmental conditions.

When inspecting blocks for wear, check headfittings for deformation, cuts, sharp edges and any damage which may produce additional stress conditions.

Check for excessive wear in pins, side plates, rope grooves, bushes and bearings. Check security of bolts, nuts and any other locking method and ensure that during continuous usage cannot vibrate loose. Any crack or deformation of a block is sufficient to withdraw the equipment from service.

The frequency of lubrication depends on product use and environmental conditions. Upon request Blue Line will provide both lubrication type and frequency.

Also available we have instructions on disassembling and assembling of blocks and sheaves.

Welding of or to load supporting parts or products can be hazardous. Knowledge of materials, heat-treatment and welding procedures is necessary for proper welding. The Blue Line should be consulted for information.

The design safety factor calculated relating the ultimate load to the working load generally expressed as a ratio.

S.W.L. (Safe Working Load) or W.W.L. (Working Load Limit) indicates the maximum mass or force which the product is authorized to support in a particular service.

Throughout the catalogue safetyfactor 5:1 is used. Meaning: Ultimate load divided by 5 = S.W.L.

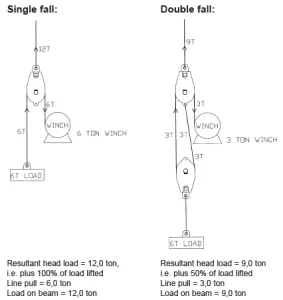

The following examples will give you guidance when deciding what you need to lift or move a load:

BMM blocks are tested on own test facilities and can be suppled with BMM-test certificate. The blocks are stamped with individual product- & certificate numbers and also shows date of production. The individual number secures easy replacement of spareparts (sheaves, bearings etc..)

The S.W.L. for Blue Line blocks indicate the maximum load that should be exerted on the block and its connecting fitting.

This total load value may be different from the weight being lifted or pulled by a hoisting or a hauling system. It is necessary to determine the total load being imposed on each block in the system to properly determine the rated capacity block to be used.

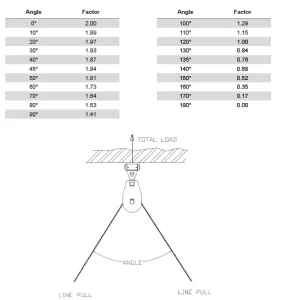

A single sheave block used to change load line direction can be subjected to total loads greatly different from the weight being lifted or pulled. The total load value varies with the angle between the incoming and departing lines to the block.

The following chart indicates the factor to be multiplied by the line pull to obtain the total load on the block.

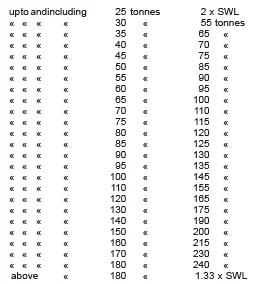

Regarding testing of trawlblocks.

Extract from the Norwegian Maritime Directorate’s Rules (§13.1.2.):

“For single sheave blocks with or without becket, the testload may

be reduced in accordance with the above table when the resultant

load in the headfitting exceeds 25 tonnes.”

When a steel wire rope is bended over a wire sheave tensions will occur.After repeatedly bendings fatigue will arise.

Exactly when this fatigue will arise depends on the sheave diameter the steel wire rope is bended over.

General recommendations is the sheave diameter (measured at the bottom of the groove) = “D” – should be 16-20 times the diameter of the wire = “Ø”.

![]()

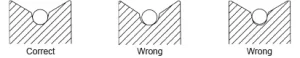

Also the groove at the bottom of the sheave has a big impact on the lifetime of the steel wire rope. The Blue Line recommends that the groove supports the steel wire rope at a minimum of 1/3 of the circumference (120 degrees).

Brdr. Markussens Metalvarefabrik A/S

Sverigesvej 5-11

DK-7480 Vildbjerg

Tlf. +45 99 92 00 00

mail: sales@blueline.dk