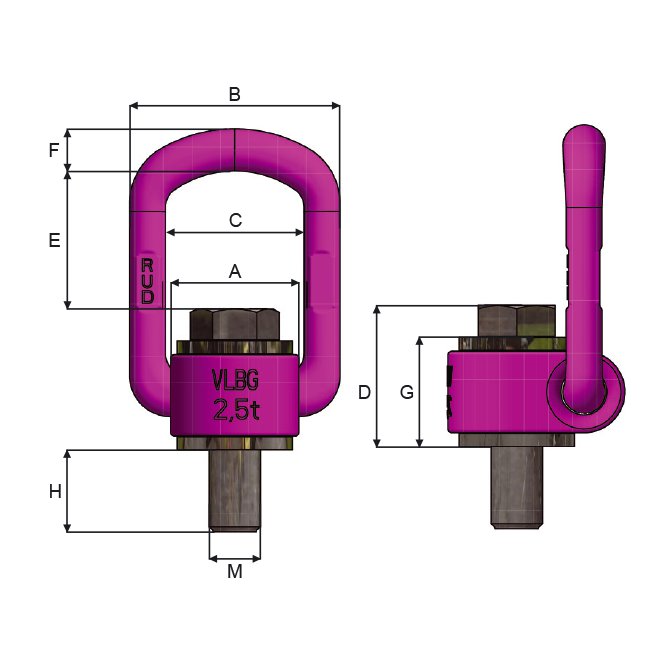

| Part no. | WLL | A | B | C | D | E | F | G | H | M | Torque | Weight |

| ton | mm | mm | mm | mm | mm | mm | mm | mm | mm | nm | kg | |

| LBG-M08 | 0.3 | 30 | 54 | 34 | 35 | 40 | 10.0 | 29 | 11 | 8 | 30 | 0.30 |

| LBG-M10 | 0.63 | 30 | 54 | 34 | 36 | 39 | 10.0 | 29 | 16 | 10 | 60 | 0.32 |

| LBG-M12 | 1.0 | 32 | 54 | 34 | 37 | 38 | 10.0 | 29 | 21 | 12 | 100 | 0.33 |

| LBG-M16 | 1.5 | 33 | 56 | 36 | 46 | 39 | 13.5 | 36 | 24 | 16 | 150 | 0.55 |

| LBG-M20 | 2.5 | 50 | 82 | 54 | 55 | 55 | 16.5 | 43 | 32 | 20 | 250 | 1.30 |

| LBG-M24 | 4.0 | 50 | 82 | 54 | 58 | 66 | 18.0 | 43 | 37 | 24 | 350 | 1.50 |

| LBG-M27 | 4.0 | 60 | 103 | 65 | 78 | 69 | 22.5 | 61 | 39 | 27 | 400 | 3.10 |

| LBG-M30 | 5.0 | 60 | 103 | 65 | 80 | 67 | 22.5 | 61 | 49 | 30 | 500 | 3.10 |

| LBG-M36-07 | 7.0 | 60 | 103 | 65 | 72 | 74 | 22.5 | 55 | 52 | 36 | 700 | 3.30 |

| LBG-M36-08 | 8.0 | 77 | 122 | 82 | 100 | 97 | 26.5 | 77 | 63 | 36 | 800 | 5.80 |

| LBG-M42-10 | 10.0 | 75 | 145 | 80 | 103 | 64 | 30×20 | 77 | 73 | 42 | 1000 | 6.40 |

| LBG-M42-15 | 15.0 | 95 | 156 | 100 | 113 | 110 | 36.0 | 87 | 63 | 42 | 1500 | 11.20 |

| LBG-M48 | 20.0 | 95 | 156 | 100 | 117 | 105 | 36.0 | 87 | 73 | 48 | 2000 | 11.20 |

The material construction to which the lifting point will be attached, should be of adequate strength

to withstand forces during lifting without deformation. RUD, with reference to the German testing

authority BG, recommends the following minimum for bolt lengths:

1.5 x M in steel (minimum quality S235JR )

1.5 x M in cast iron (for example GG 25)

2 x M in aluminium alloys

2.5 x M in aluminium-magnesium alloys

( M = diameter of RUD lifting point bolt, e.g. M 20 )

Brdr. Markussens Metalvarefabrik A/S

Sverigesvej 5-11

DK-7480 Vildbjerg

Tlf. +45 99 92 00 00

mail: sales@blueline.dk